This article was published in Scientific American’s former blog network and reflects the views of the author, not necessarily those of Scientific American

When Felipe Gomez was in high school, he became interested in how you could improve the safety and efficiency of jet engines. He began studying the phenomena of plasma-assisted fuel injection and exploring how the process worked in his garage. Gomez built his first prototype system using a Bunsen burner from school and propane from his family’s gas grill.

Four years later, Gomez is double-majoring in mechanical and aerospace engineering and is the sole inventor behind two patented plug-and-play, plasma-assisted fuel injection systems. Though technically a junior at Case Western Reserve Univeristy, Gomez is already taking graduate classes and conducting research – all while clocking 20 hours in the pool each week as a NCAA swimmer.

His company, FGC Plasma Solutions LLC, now owns both of Gomez’s patents and has gained national attention by winning the 2015 Clean Energy Trust Clean Energy Challenge in Chicago and competing in the 2015 National Clean Energy Business Plan Competition in Washington, D.C. last month. In May, as a part of the President’s announcement for new efforts to support emerging entrepreneurs, Gomez was recognized for his innovation and took part in a panel discussion at the White House with “Shark Tank” investors Barbara Cocoran, Daymond John and Mark Cuban.

On supporting science journalism

If you're enjoying this article, consider supporting our award-winning journalism by subscribing. By purchasing a subscription you are helping to ensure the future of impactful stories about the discoveries and ideas shaping our world today.

His team includes fellow students Joe Scott and Joe Heebner. The former is a finance major at Case Western. The latter is a mechanical engineer with a strong interest in fluid mechanics and combustion research.

When I spoke with Gomez this month, he explained his technology, why he is working on it, and what he hopes will come from this novel way to improve aircraft safety and decrease fuel consumption in jet engines:

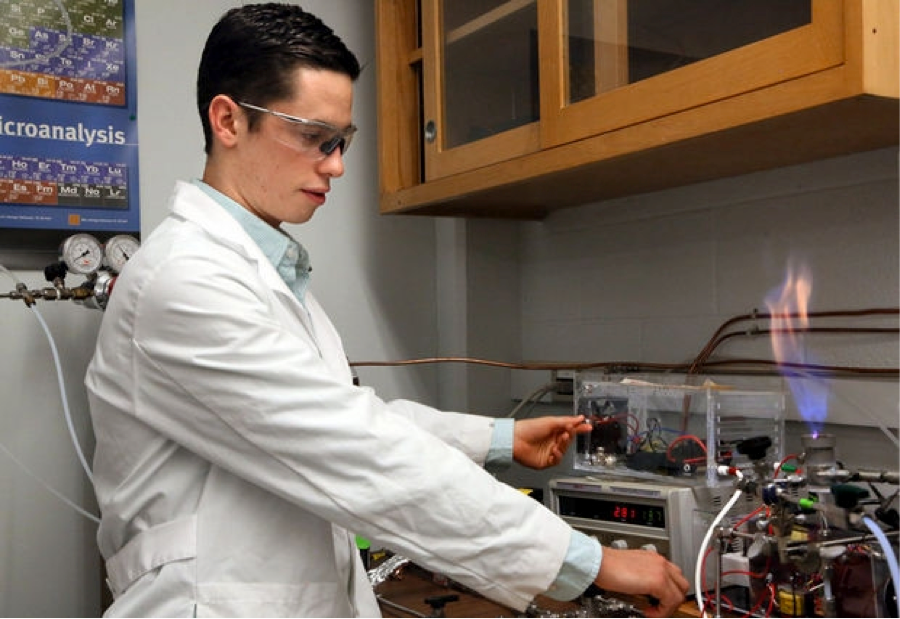

Felipe Gomez demonstrating plasma-assisted fuel injection in a research lab at Case Western Reserve Univeristy

Lott: How did this work begin? When did you start really experimenting with plasma-assisted combustion?

Gomez: This all started as a high school science fair project. The phenomena of plasma-assisted combustion isn’t new. I read some papers about it in high school and thought it was interesting. So, I started on a proof of concept in my garage. I worked with a Bunsen burner, a high voltage power supply and a propane tank from our backyard grill to alter the kinetics of the combustion process.

Geometrically, this meant applying an electric field to the base of the flame. At first, there were some pretty impressive fireworks. The garage was right in view of my neighbour, who was the fire marshal, and I could see him poking his head up at a window while I worked.

Lott: How did this project develop after your work in the garage?

Gomez: After my proof of concept in my garage I took it to the science fair and started to see the potential for some really interesting applications. I then got a scholarship to attend Case Western Reserve University and took my prototype there to keep working on it. At Case, I began looking at where it could be best used and settled on jet engines – though it could also be used in gas turbines in power plants to improve efficiency.

I then looked at how it could be best applied in jet engines and began working on a new fuel injector design. This design is what I have been working on at Case. Today, we have two patented fuel injector technologies - the Gliding Arc Lean Direct Injection (GALDI) and Gliding Arc Lean Premixed Prevaporized (GALPP) - that allow combustors to operate at lower equivalence ratios, which refers to the mixture of fuel and air used by the jet engine. By lowering the ratio, you are lowering the amount of fuel you need to run your aircraft. As a result, you increase the overall fuel efficiency of your jet engine.

Lott: Is this work all about increasing fuel efficiency? Or is safety another aspect of the work?

Gomez: Safety is a small aspect, because jet engines are extremely safe already. But, since you are making the combustion process more stable with plasma-assisted combustion, you make the engine less susceptible to problems with flame-outs – though these are rare in today’s jet engines.

A flame-out in jet engines is whenever combustion in the engine extinguishes. This generally happens when combustion becomes unstable, which can happen when something with the flow gets messy or the fuel-to-air ratio gets too low and the flame can't exist because it can’t generate enough heat to sustain itself.

With plasma, we can increase the flammability of the fuel mix, decreasing the minimum fuel-to-air ratio. This can be important, for example, when a plane flies through a thunderstorm and there’s a lot of water in the air and that water tries to extinguish the flame. With plasma, you can keep that flame stable and prevent potential problems.

Plasma can also allow you to maintain or ignite your flame at high altitudes, where there’s not enough oxygen and temperatures are too low to maintain a flame.

Again, these are very rare situations and problems. Our value proposition isn’t primarily in safety – it’s in fuel efficiency. But, the technology does support safer operation.

Lott: In terms of fuel efficiency, are we actually spending more fuel today because we need to have more chemical energy into the combustion process to avoid blowouts? How does plasma help you to get the power that you need?

Gomez: Inefficiencies in jet engine combustion occur when you have incomplete combustion – either when you don’t have enough air to oxidize the fuel or the fuel doesn’t have enough time to burn. Jet engine combustors are already highly efficient, except when they are idling.

What we are doing only really helps on the fuel efficiency side at very low power settings. Our technology increases the efficiency of the jet engine when it is idling, taxiing, or descending at a very low power setting. Plasma allows you to lower the amount of fuel you need at these low power settings to keep the flame from going out.

Basically, jet engines are currently using about twice as much fuel as they need to during these low power setting periods – such as when you’re sitting on the runway waiting to take off. This fuel use adds up.

Lott: What about local air pollution, like nitrogen oxide (NOx)?

Gomez: The industry is quite conscious of things like air pollution and has been working to reduce pollution levels. Today’s jet engines pollute much less than old ones. Our technology reduces NOx further than what you would see with just improving efficiency. Not only does our technology reduce the amount of fuel needed to maintain combustion but it also lowers the combustion temperature.

We have two technologies – to improve the efficiency of two different types of combustion systems that the industry is already moving toward. These are the direct injection and premixed pre-vaporized systems.

Lott: We have spoken a lot about jet engines – where do gas turbines and power plants enter the picture?

Gomez: I’m a huge aerospace nerd so the aerospace market always interested me the most. But, a few people on the business side who are advising me said that six to eight year time-to-market thing for jet engines isn’t going to work for any investor. Maybe even for anyone who wants to be in the company. So, we needed to find a market that we could enter into earlier. That’s how power plants entered the picture.

Gas turbines operate the same as jet engines. But, you don’t have a strict air worthiness requirement like you do with technologies for planes. The regulations and factor of safety requirements aren’t as strict because, if it fails, no one is going to die. A plane isn’t going to crash.

The more we researched the gas turbine market, the more we saw things like the fact that NOx emissions restrictions are 20 times stricter on gas turbines than jet engines. They are maybe not as fuel conscious, but there are still a lot of problems that we could solve for power plants.

Since gas plants are so worried about NOx emissions, they try to run their plants a lot leaner. With plasma, we can increase their flame stability. For spinning reserve and peaker plants, we can let them idle at a very low speed – this saves wear and tear on the engine because you don’t have a big amount of thermal cycling each day.

The good news is that the commercialization paths for jet engines and gas turbines run somewhat in parallel. The companies making the gas turbines often make the jet engines as well. So, it would help us to develop our relationship with them and it would help them to solve some of their problems in both jet engines and gas turbines.

Lott: How has your work changed from when you were in your garage in high school to today at Case Western Reserve University?

Gomez: The big change is that, at first, I looked at this as a pure research project. But then I realized that I could get a lot more funding to work on the project if I turned it into a company. So, I did that my sophomore year.

I think that what I really enjoy the most is the research. But, with that, I think that research is pretty useless if it doesn’t go anywhere. So, I think that the process of taking this research out of the lab, doing it as a business, and seeing what the market really needs has made this research a whole lot more important than just playing around in the lab with something that you think is cool. So, getting to do both research and business is really cool. But, fundamentally, I’m more of a researcher.

Lott: Who all is involved in the work?

Gomez: I have some faculty advisors including Professor James T’ien, Professor Joe Prahl, Professor Mohan Sankaran and Mindy Baierl, a technical engineer (now our VP of research), and a CFO – all from Case Western. I met our VP of research, Joe Heebner, in my graduate combustion science class and he is also an athlete. I was housemates with Joe Scott, our CFO. He knows all about finance and I don’t, so I drafted him.

Lott: What’s next for you once you graduate?

Gomez: Graduate school is definitely happening. I might first do a one-year master's here at Case before doing my PhD somewhere. I came in with a lot of credits and have taken some graduate classes already, so would just need to write my thesis for that. We will see.