This article was published in Scientific American’s former blog network and reflects the views of the author, not necessarily those of Scientific American

Most scenarios for a clean-energy future rely on carbon capture—taking CO2 emissions from their sources, such as power plants, then sequestering them underground or converting the carbon into a usable product like smart concrete. While making carbon capture economically viable has long faced significant challenges, this environmentally friendly technology may finally be on the threshold of success.

There’s been a resurgence of interest in CO2 sequestration recently in the United States, mostly because the federal government increased corporate tax credits. For businesses, the pitch is straightforward: spend money on carbon-capture technology in the short term, then earn a tax credit on every metric ton of CO2 prevented from entering the atmosphere. With larger emitters able to capture millions of tons each year, this quickly becomes profitable, while at the same time reducing greenhouse emissions. It’s a true win-win for all.

By 2025 the Department of Energy plans to create vast, regional carbon sequestration programs across the country by partnering with private utilities. But while researchers developed the science behind removing and storing carbon emissions decades ago, connecting an emitter to a storage center has always posed problems.

On supporting science journalism

If you're enjoying this article, consider supporting our award-winning journalism by subscribing. By purchasing a subscription you are helping to ensure the future of impactful stories about the discoveries and ideas shaping our world today.

For example, at the National Carbon Capture Center in Alabama, where the DOE has tested the technology since 2009, equipment on the coal power plant’s smokestacks separates the carbon from other emissions. The byproduct is then transported in the form of liquid to a storage sink, a subterranean reservoir full of the same porous, sedimentary rock found in Zion National Park—except that the rock exists thousands of feet below the earth’s surface.

At this depth, carbon can be stored below a caprock layer, a virtually impenetrable stratum of rock, most often shale. Sometimes these carbon capture sinks already exist in the form of prior oil extraction projects. Most importantly, transportation costs between emitter and sink must be kept lower than the tax credit so companies can profit, a condition without which they’re not likely to invest in the technology.

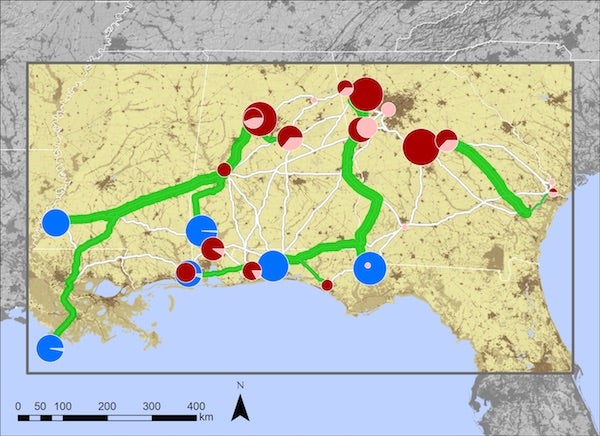

This map from the SimCCS software developed by Los Alamos National Laboratory shows potential carbon sources (red dots), sinks (blue dots), and proposed optimal pipelines (green). Oil companies and government agencies are using SimCCS to figure out how to turn a profit from selling CO2. Credit: Los Alamos National Laboratory

SimCCS is a software program developed at Los Alamos National Laboratory to solve that problem. The open-source software, which is also being developed and expanded on by universities across the country, finds the most efficient route between a carbon-emitting plant and a sink.

Much like you might consider time of day, weather, and road conditions for your commute home, SimCCS weighs variables. With commuting, those might be a choice between a freeway choked with traffic or a less crowded road with slower speed limits. With carbon sequestration, SimCCS considers factors like building carbon transmission pipelines on private land, which may be too expensive compared to public land. Or perhaps hills and canyons make the terrain cost-prohibitive. Often the cheapest choice is to piggyback alongside existing energy pipelines and, similarly, to use existing but inactive oil wells as sequestration sinks. But how much does that cost? And where are these existing pipes and sinks?

The program was designed to analyze these factors, along with a given carbon tax credit amount, then display route options and profitability on a layered map. A red dot marks emitters in a region and the dot’s radius indicates how much CO2 the plant produces. Sequestration sinks are blue, with green lines connecting origin and destination, much like the GPS app on your phone that guides you around traffic.

The math tells the story: If SimCCS can keep the costs of capture, transfer and storage to $40 a ton, with a carbon tax credit of, say, $50, this would not only eliminate nearly all CO2 emissions from a coal plant (more than 100,000 hours of DOE testing shows carbon capture removes 90 percent of emissions), but the utility would turn a $10-a ton profit. At a medium-sized plant that emits 10 million metric tons of carbon each year, that’s $100 million.

SimCCS has already mapped regions in the South, Upper Midwest, and the West’s Four Corners area, with plans to develop this technology further as the DOE pushes its regional 2025 carbon sequestration program.

A path to a clean-energy future, which helps our national energy independence, relies on carbon sequestration. The fastest way to spread this technology is by attracting private utilities, and that means keeping costs down as companies move this greenhouse gas from plant to sink, where it can be kept out of our atmosphere.