This article was published in Scientific American’s former blog network and reflects the views of the author, not necessarily those of Scientific American

Five student teams will compete in Washington, DC next week in the fourth annual National Competition in the U.S. Department of Energy’s National Clean Energy Business Plan Competition (NCEBPC) series. Each of these teams has previously won a regional business plan competition in order to advance to the June 24 finals.

Next week’s winner will take home a “$50,000 National Prize as well as unique in-kind services to help commercialize their technology” reports Jennifer Garson, from the DOE’s Office of Energy Efficiency and Renewable Energy. Competing in the finals will be:

FGC Plasma Solutions – these students, from Case Western Reserve University, have developed a novel way to inject fuel into jet engines using plasma to modify the combustion reaction. Their plug-and-play solution could improve safety while decreasing fuel consumption by approximately 10 percent. Winner: Eastern Midwest Region – Clean Energy Challenge run by the Clean Energy Trust

Hyliion (Carnegie Mellon University) – this student team has developed an add-on hybrid module for tractor-trailers that captures otherwise wasted energy to reduce fuel consumption by 30 percent. Installed underneath the trailer, the SMART Suspension system stores the energy lost while braking and coasting down hills to power the truck’s acceleration, reducing greenhouse gas emissions. It has the potential to save companies an average of $29,000 per tractor-trailer per year. Winner: Western Southwest Region – DOE Clean Tech Prize, Rice Business Plan Competition run by Rice University

Living Ink Technologies (Colorado State University) – this team has developed a patent-pending technology that uses algae to transform carbon dioxide into a cheaper, healthier, and environmentally sustainable ink. Their plan is to initially focus on the toy, greeting card, and promotional products space with the goal of eventually transforming the ink industry as a whole. Winner: Western Midwest Region –CU Energy Competition Regional Championships run by University of Colorado-Boulder

Axiom Exergy (Stanford University) – these students have developed a way to reduce the electricity demand from supermarkets during peak hours by shifting the bulk of refrigeration-related energy usage to cheaper off-peak hours using the Refrigeration BatteryTM. This thermal energy storage retrofit allows supermarkets to freeze water in tanks overnight for use during the day and can reduce storewide electricity bills by 20%. Winner: Western Region – First Look West (FLoW) 2.0 Cleantech Competition run by California Institute of Technology.

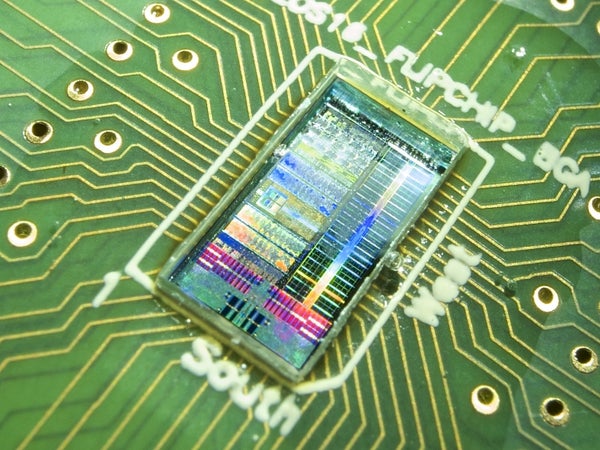

OptiBit (MIT, University of California-Berkeley, and University of Colorado-Boulder) – students from across these three universities have developed a way for data centers to save energy by 1) bringing the high bandwidth and energy efficiency of fiber optics to computer chips and 2) using a drop-in phototonics hardware solution with 10 times more throughput, two times lower latency, and 95 percent less energy use than the current copper-based technology. According to the Department of Energy “the company’s patented technology ties in with the Obama administration’s efforts to reduce the federal government’s energy use, including cutting consumption in data centers” and was developed over a period of 10 years. This is the first multi-university student team to win a regional NCEBPC competition. Winner: Northeast Region – MIT Clean Energy Prize

On supporting science journalism

If you're enjoying this article, consider supporting our award-winning journalism by subscribing. By purchasing a subscription you are helping to ensure the future of impactful stories about the discoveries and ideas shaping our world today.

A previous Plugged In article on Hyliion’s success at the Rice Business Plan Competition can be found below:

Hyliion Takes Home Big Prize at Rice Business Plan Competition With Its Hybrid 18-Wheeler (April 24, 2015)

Hyliion team members Thomas Healy, Mario Avila, and Hayden Cardiff stand with their slide-in suspension system prototype. Photo Credit: Melissa C. Lott

On Saturday, a start-up called Hyliion was awarded the U.S. Department of Energy Clean Energy Entrepreneurship prize at the 15th annual Rice Business Plan Competition in Houston.

This Pittsburgh-based and student-led company has developed a slide-in suspension system for tractor-trailers that could reduce fuel use in these trucks by 31%. With an anticipated price tag of just $25,000, this fuel savings is all the more impressive. So much so that the company took home a total of $162,500 in prizes on Saturday. In addition to the DOE prize, they were awarded $10k from Shell, $15k from Wells Fargo, $80k from SURGE Ventures, and $7,500 for their 3rd place overall finish.

The concept behind Hyliion was initially conceived by its Co-Founder Thomas Healy, a current Master’s student in Mechanical Engineering at Carnegie Mellon University (CMU). Healy found his love for race car driving when he was just nine years old and, with competitions around the country, he became quickly used to following 18-wheelers full of racing gear down long highways. When his parents gave him a hybrid Honda Civic for his off-track car at the age of sixteen, Healy began to wonder – “why aren’t tractor trailers using hybrid technology?”

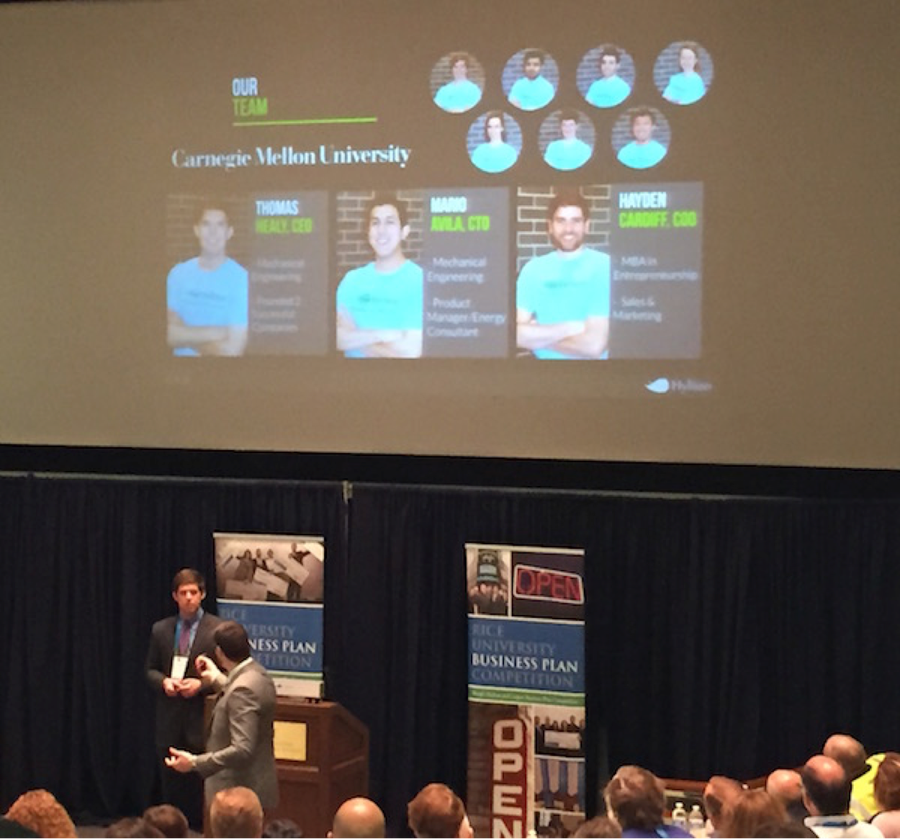

Fast-forward six years and Healy has paired up with fellow CMU students including Co-Founder Mario Avila and Hayden Cardiff to create a working prototype of their “add-on hybrid module for tractor trailers.” Avila recently completed a dual-masters degree program in mechanical engineering and a CMU-specific program called Engineering & Technology Innovation Management while Hayden Cardiff is working toward his MBA. Today, their team includes another seven CMU students and a group of strategic advisors that includes electric vehicle experts, truck and fleet owners, entrepreneurs, and an astronaut.

Healy and Cardiff present final-round pitch at Rice Business Plan Competition in Houston on Saturday. Photo Credit: Melissa C. Lott

The Hyliion team built their prototype at an off-campus workshop near Carnegie Mellon and maintain all rights to its patent-pending technology. The module is designed to recover energy through regenerative braking, store that energy in a pack of lithium-ion batteries, and then use it later to assist with acceleration and braking, as well as maintaining comfort in the truck’s cab while the vehicle is idle. The system is installed on the rear axel of the trailer and also includes a drag reduction plate.

Healy standing in front of the Hyliion prototype, while showing its intended place on a trailer model. Photo Credit: Melissa C. Lott

While the system is called a “hybrid” module, it is different than the hybrid-electric system that Healy found in his Civic. Specifically, the diesel engine and the electric motor are maintained in two separate parts of the rig and are not directly connected. Furthermore, the electric motor is not used directly for propulsion. Rather, it is designed to assist the truck as it goes up and down hills along the road. Changes in elevation are anticipated and recognized using an on-board computer and proprietary software designed in-house.

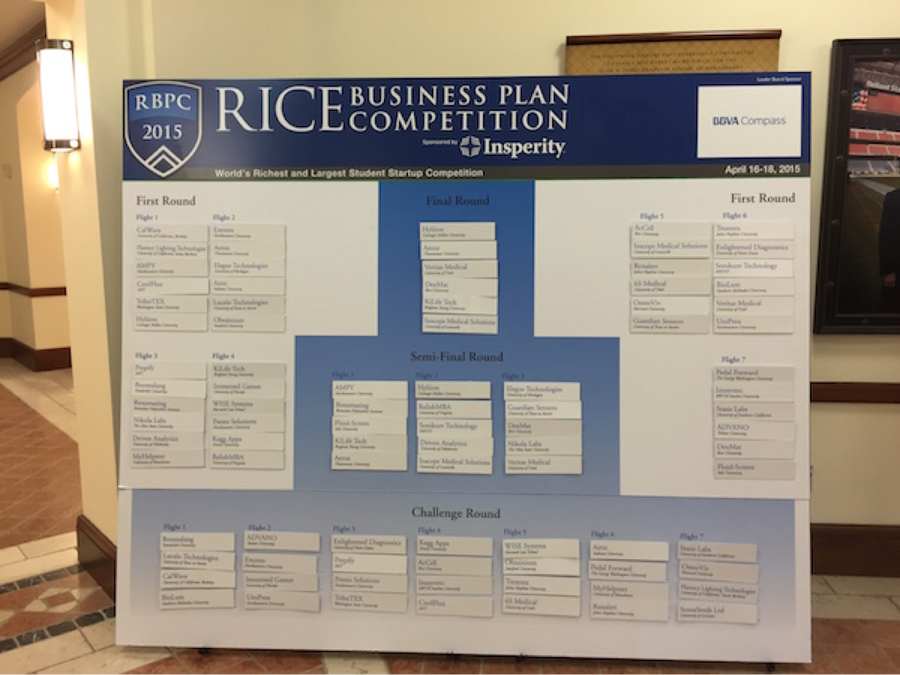

Hyliion took 3rd place overall in the Rice Business Plan Competition, behind Brigham Young University’s KiLife Tech and University of Louisville’s Inscope Medical Solutions. The competition itself began in 2001, with a set of 9 student start-up companies competing for $10,000 in prize money. This year, 42 teams from a pool of more than 1,200 applicants competed for upwards of $1.5 million. Judges and mentors also provided multiple rounds of feedback for the teams as they progressed through three days of business plan pitch evaluations.

Business Plan Competition Standings Going into the Final Round of Pitches Photo Credit: Melissa C. Lott